Let’s start with a simple explanatory slogan: “cement is to concrete as flour is to bread.” Therefore, you don’t walk on a cement sidewalk or park you car on a cement driveway. That said, I am sure that our professional readers know this, but perhaps our more casual fans of architecture might not.

Definitions:

Per the American Concrete Institute (ACI)

Concrete is a composite material that consists of a mixture of hydraulic cement, aggregates, and water, with or without admixtures, fibers, or other cementitious materials.

Hydraulic cement is cement that sets and hardens by chemical reaction with water (hydration) and is capable of doing so under water (ACI 225R). The hydration reactions result in the formation of a hard solid mass. The most widely used hydraulic cement is portland cement.

Mortar is a mixture of cement paste and fine aggregate; in fresh concrete, the material occupying the interstices among particles of coarse aggregate; in masonry construction, joint mortar may contain masonry cement, or may contain hydraulic cement with lime (and possibly other admixtures) to afford greater plasticity and workability than are attainable with standard portland cement mortar.

Grout is a mixture of cementitious materials and water, or other binding medium, with fine aggregate.

History

According to International Association of Home Inspectors:

6500 BC

The first concrete-like structures were built by the Nabataea traders or Bedouins who occupied and controlled a series of oases and developed a small empire in the regions of southern Syria and northern Jordan in around 6500 BC. They later discovered the advantages of hydraulic lime -- that is, cement that hardens underwater -- and by 700 BC, they were building kilns to supply mortar for the construction of rubble-wall houses, concrete floors, and underground waterproof cisterns. The cisterns were kept secret and were one of the reasons the Nabataea were able to thrive in the desert.

Roman Era

The Romans significantly advanced concrete technology. They used a mixture of lime, volcanic ash (pozzolana), and aggregate (like pumice) to create a strong, durable material known as "opus caementicium". They utilized this concrete for various structures, including bridges, docks, aqueducts, and iconic buildings like the Pantheon.

Twentieth Century

We have discussed the use of concrete in the twentieth century previously in this space, particularly as it was used in Brutalist Architecture , part of the rational for the use of concrete as a standard was:

The late 40s and early 50s needed desperately to rebuild from the war’s destruction. The competition for building materials led architects to favor reinforced concrete since it was relatively inexpensive and reasonably available

The paragraph above refers to “reinforced concrete.” Therefore, let’s discuss a few 20th century concrete upgrades.

Steel Reinforced Concrete

A simple definition of steel reinforced concrete can be gathered up using Chat GPT:

Steel reinforced concrete is a composite material combining the compressive strength of concrete with the tensile strength of steel. Steel, in the form of rebar or mesh, is embedded within the concrete to strengthen it against tension, shear, and bending forces, making it suitable for a wide range of structural applications

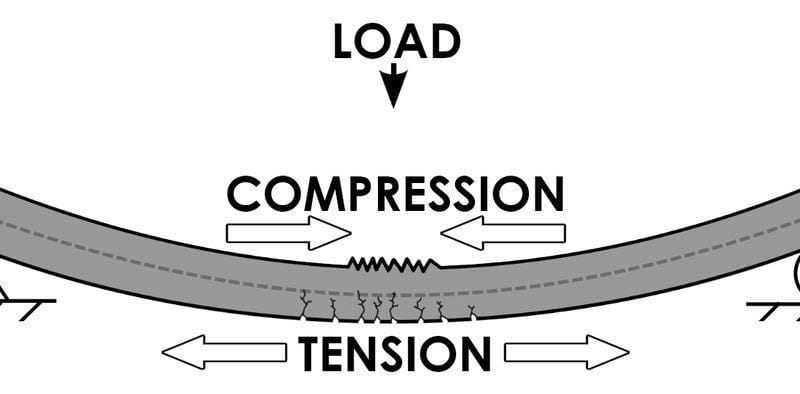

Concrete is very strong in compression, it can handle very heavy forces pressing down on it without experiencing failure. Naturally this is for supporting weight and handling pressure. But there is a big BUT. In terms of tension — forces that try to pull it apart — concrete is much weaker, with tensile strength usually less than 10% of its compressive strength. Steel reinforcement begins to solve this problem:

The rebar that you can see above circled in blue provides increased resistance to cracking, vibration and potential bending. The nest step in the evolution of the materials was GFRC (Glass Fiber Reinforced Concrete)

GFRC

According to the concrete Countertop Institute:

GFRC, or Glass Fiber Reinforced Concrete, is a versatile, high-performance concrete mix that incorporates alkali-resistant glass fibers to produce a material with exceptional strength and reduced weight. Widely used in architectural applications such as building cladding, GFRC concrete is an ideal choice for countertops, wall panels, and custom concrete surfaces.

The same organization lists a few of the GFRC critical advantages:

1.Design Flexibility

2.Lightweight Composition

3.Durability in Diverse Environments

4.Enhanced Flexural and Tensile Strength

UHPC

The next step in concrete development and utility seems to be here.

uhpcsolutions.com tells us this:

UHPC) is a new class of concrete that has been developed in recent decades for its exceptional properties of strength and durability. This high performance concrete can be utilized in structural rehabilitation and accelerated bridge construction in addition to several other applications. Read on to learn more about the history of UHPC, its composition and applications.

UHPC was first used by the U.S. Army Corps of Engineers in the late 1980’s and became available in the US in 2000. The commercial availability of UHPC allowed the Federal Highway Administration (FHWA) to start investigation in order to use UHPC for highway infrastructure. The FHWA investigations led to additional research from universities and demonstration projects. The result was a body of publications on UHPC and a long list of “bridge applications” including:

UHPC has a compressive strength 10 times that of traditional concrete. Compressive strength is the ability of a material to resist bending under a load (or in compression). Normal concrete used in bridges has a compressive strength of 3,000 to 5,000 psi. UHPC has a compressive strength of 18,000 to 35,000 psi. Another measure of strength is tensile strength or tension. This is how strong a material is when you pull it. While traditional concrete has a tensile strength of 400 – 700 psi, UHPC has a tensile strength of about 1400 psi.

UHPC has proven its utility in bridge construction in particular. The combination of compressive and tensile strengths has proven irresistible to engineers faced with public sector budgets, aggressive political timelines, and strict technical performance standards.

Conclusion on Concrete 2025

Having recently passed a milestone of forty five years spent in the architectural products ecosystem, I am struck by the great advances in concrete that have been made. In that time period, concrete has taken on more roles, is more technically capable of performing in those roles , all the while looking better in the process.